Hot LIne:

0769-88087226

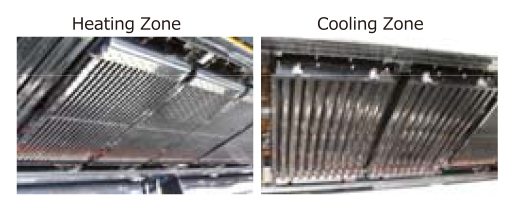

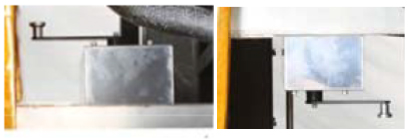

New type of air nozzle improves temperature uniformity

A new type of air nozzle that reduces heating temperature fluctuations

ETC's specially designed new air nozzle and fine 5-speed wind speed setting can uniformly heat various types of circuit boards with small temperature differences The structure of the cooling zone air nozzle can also effectively prevent the dripping of solder flux

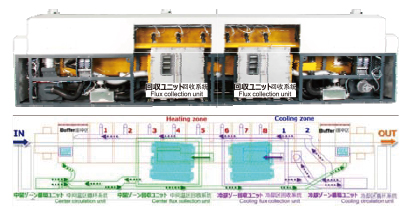

Efficient and high-capacity flux collection performance

According to the atomization characteristics of the flux and the convection characteristics of the air inside the furnace, two sets of high-efficiency air-cooled recycling units are configured to recover the flux.

Uniform oxygen concentration control system for the entire furnace

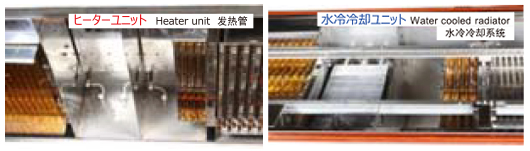

Install a heater above the entrance and exit where there is a lot of flux adhesion, and install an air-cooled cooling device below to prevent flux adhesion and dripping

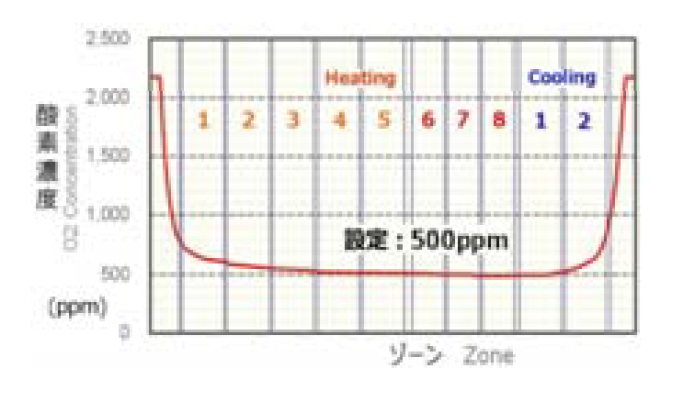

Uniform oxygen concentration control system for the entire furnace

The entire furnace has the same oxygen concentration

Our unique internal pressure control system can achieve the same oxygen concentration throughout the furnace with a small amount of nitrogen, effectively preventing copper oxidation of organic solder mask (OSP) circuit boards, improving the wetting and connection reliability of solder, and enhancing the welding effect

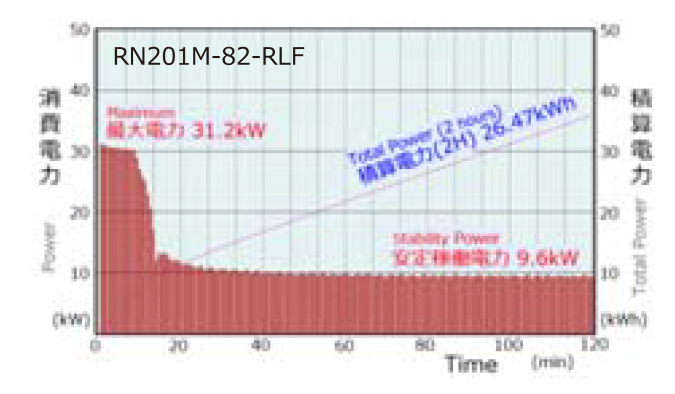

Ultra low power consumption

Lighter furnace body and high insulation specification design significantly reduce power consumption

Adopting insulation design with minimal environmental impact

Low power consumption, insulating the furnace body to a cover temperature that will not burden people or air conditioning

Simple adjustment of door curtain height

Standard manual adjustment of door curtain height, optional automatic flexible adjustment of door curtain height according to production model, effectively controlling and saving nitrogen consumption, optional automatic adjustment of door curtain height

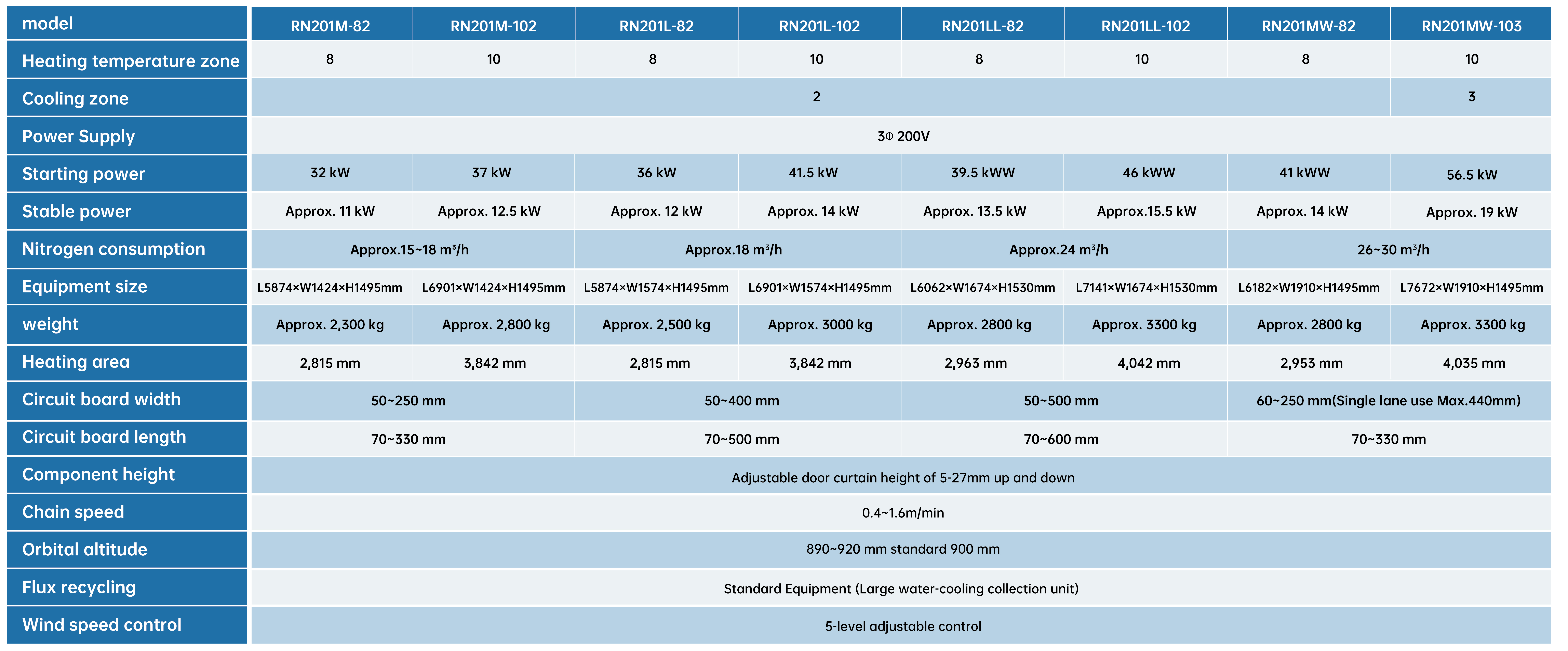

Product parameters

QR Scan