Hot LIne:

0769-88087226

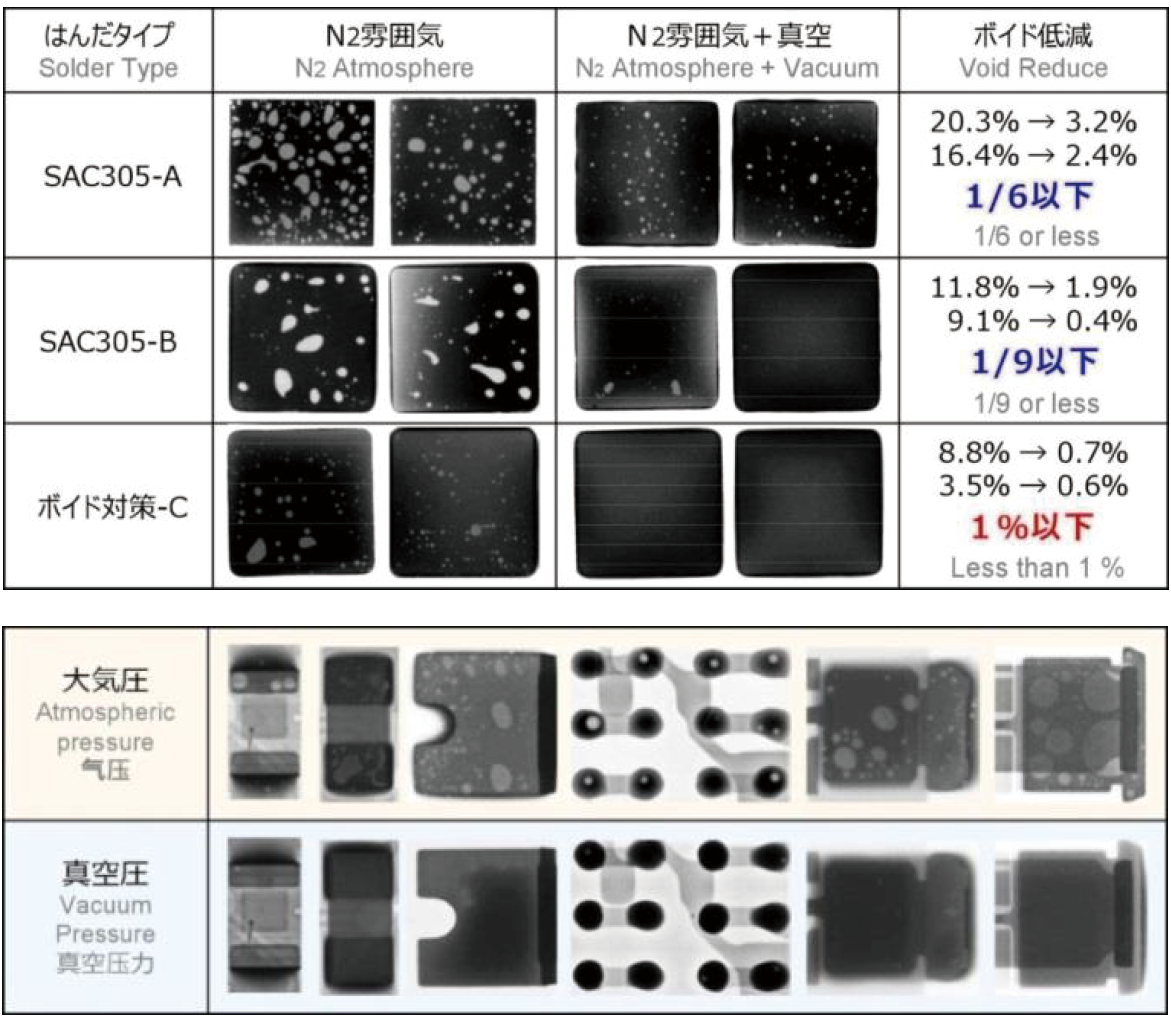

Vacuum Effect 1: Reduce Bubbles

The combination of hot air circulation heating and vacuum pressure, even for large-area component welding, can significantly reduce bubbles in a short period of time. The use of solder paste with bubble countermeasures can achieve a bubble rate of less than 1%

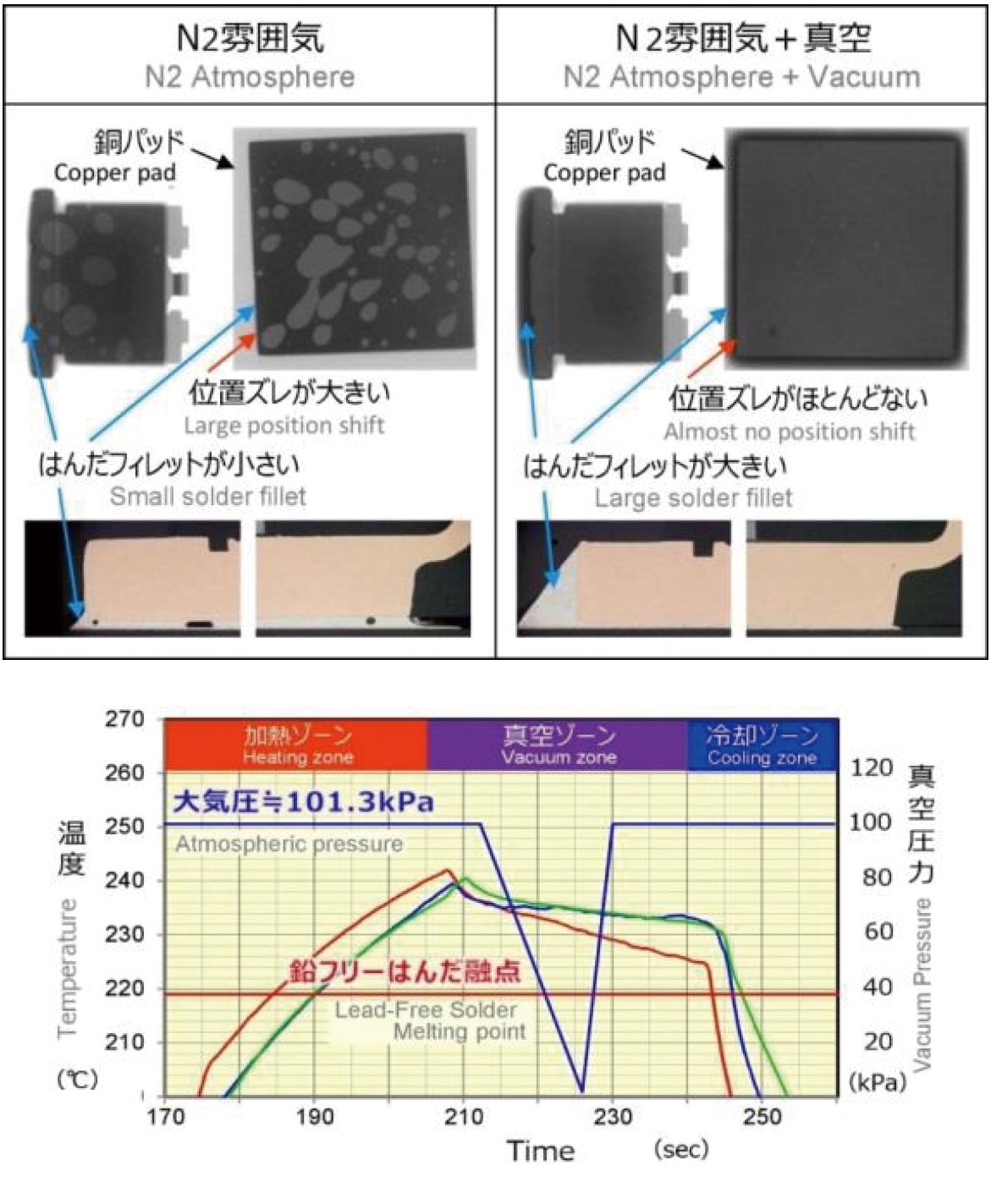

Vacuum Effect 2: Effects Other than Bubbles

• Welding automatic adjustment force increases, parts shift, and floating defects decrease

• Tin filling increases in size, facilitating visual inspection

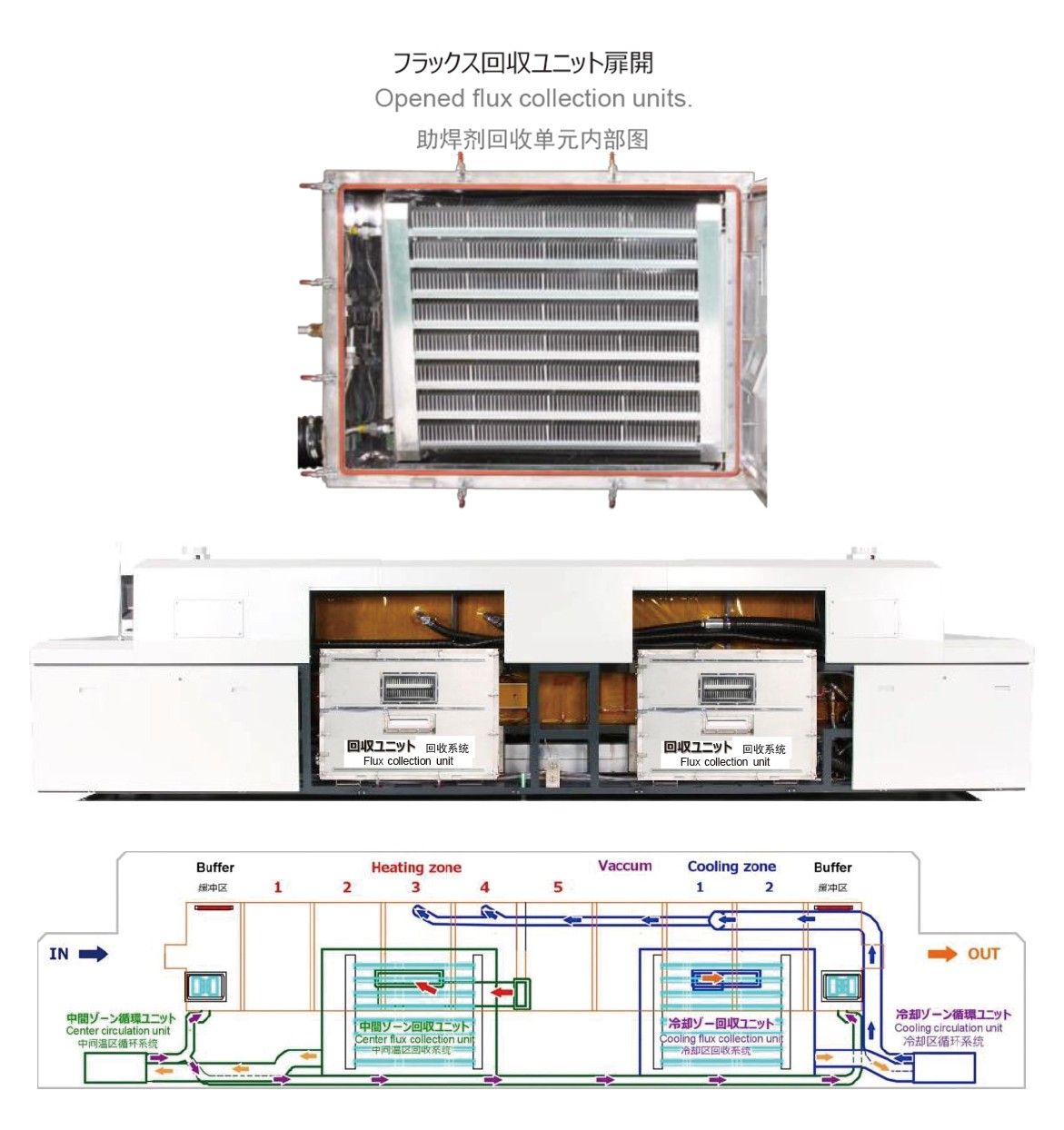

Amazing flux recycling performance

Based on the characteristics of the flux and combined with efficient air convection in the furnace, two sets of large-scale water-cooled flux recycling systems are configured to significantly reduce the frequency of flux cleaning The recycling efficiency is unparalleled!

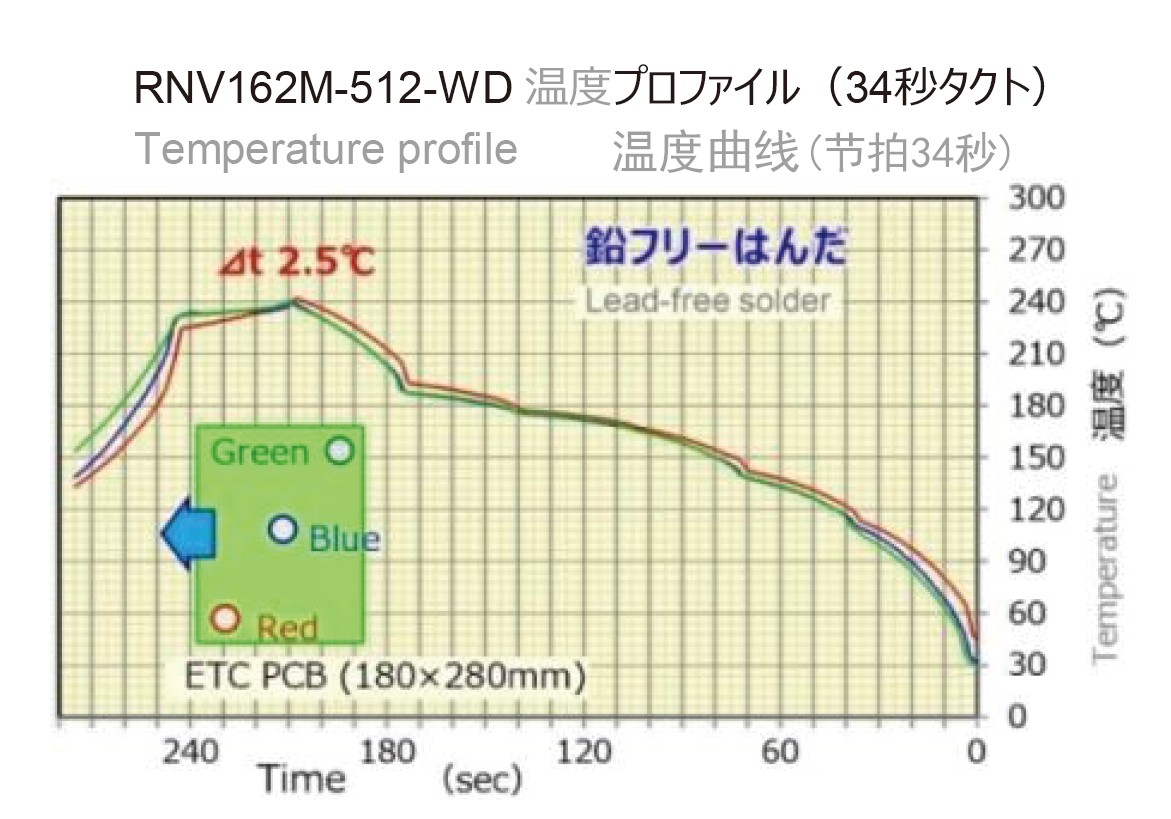

heating performance

• Compared to the heating method of the heating plate, the temperature fluctuation is small, the thermal conductivity is high, and the reflux time is short

• Welding of corresponding aluminum radiator circuit board components

The combination of upper and lower hot air circulation and vacuum pressure can achieve high-quality welding performance far beyond the traditional reflow soldering concept, even in a small temperature zone.

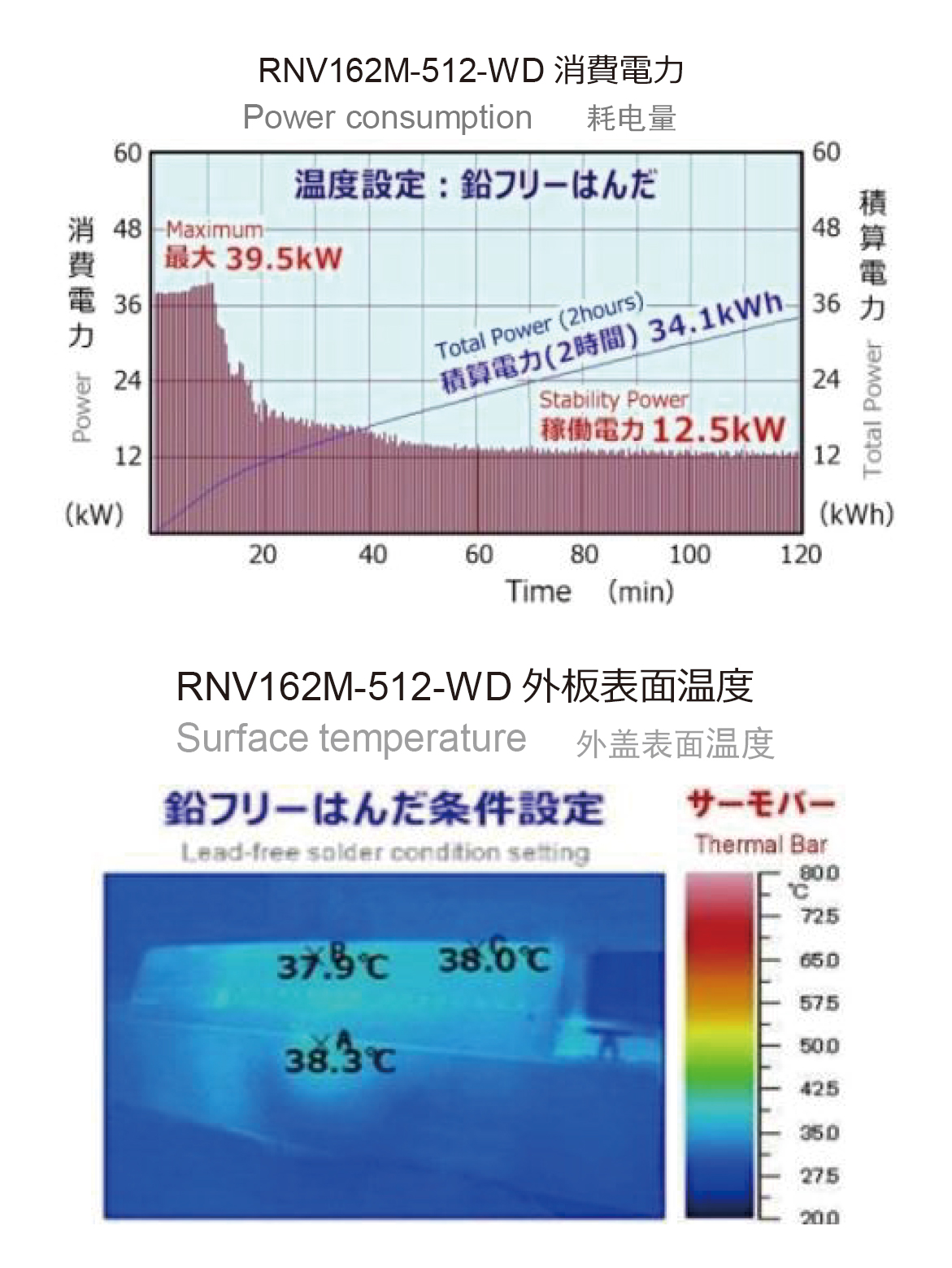

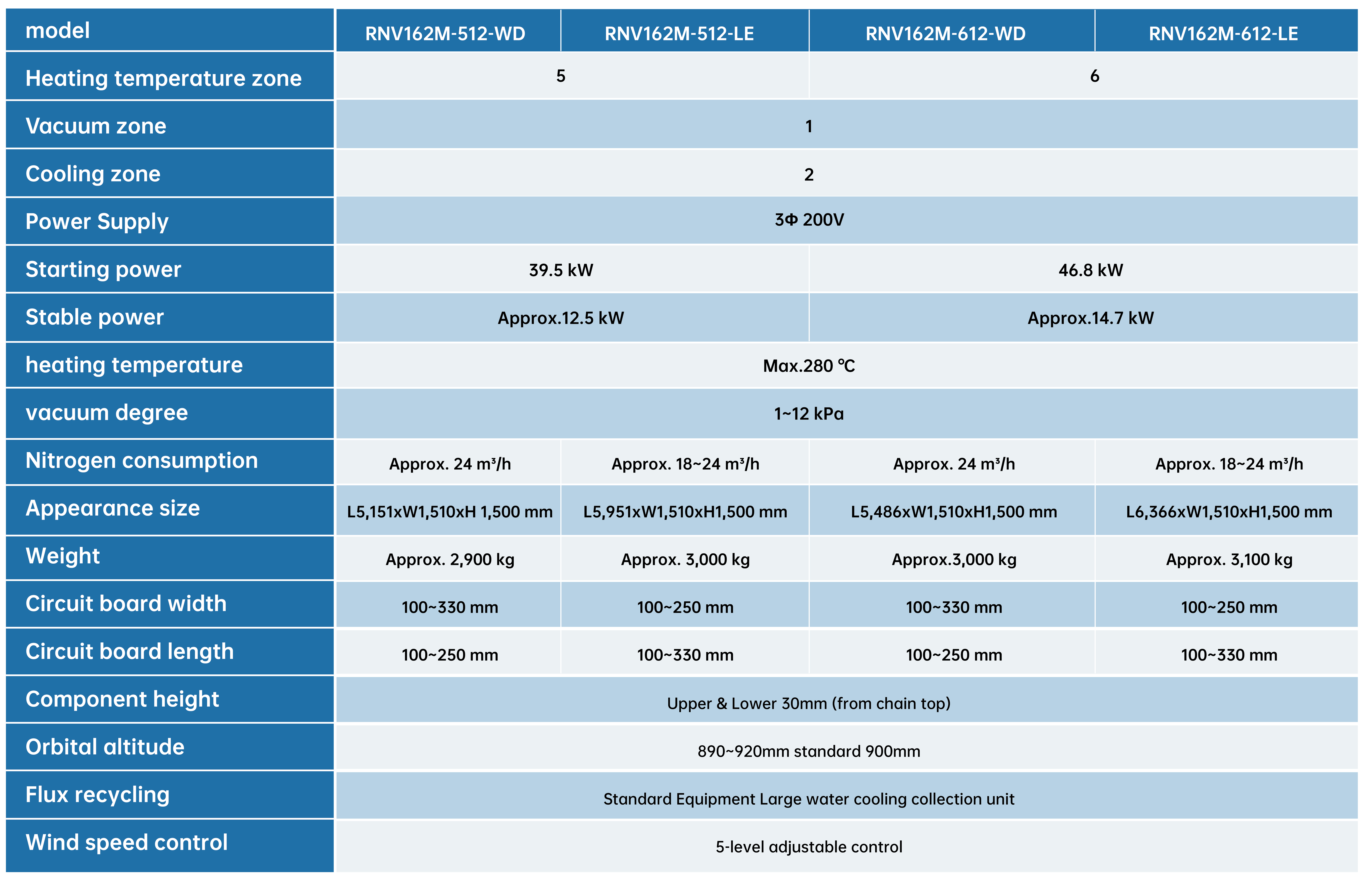

Low power consumption with minimal environmental and cost impact

• High insulation design with ultra-low power consumption even with water cooling system included

• Lightweight and high insulation of the furnace body, achieving ultra-low energy consumption, saving energy, and reducing CO2 emissions. Energy saving, emission reduction, and cost saving.

Product parameters

QR Scan