Hot LIne:

0769-88087226

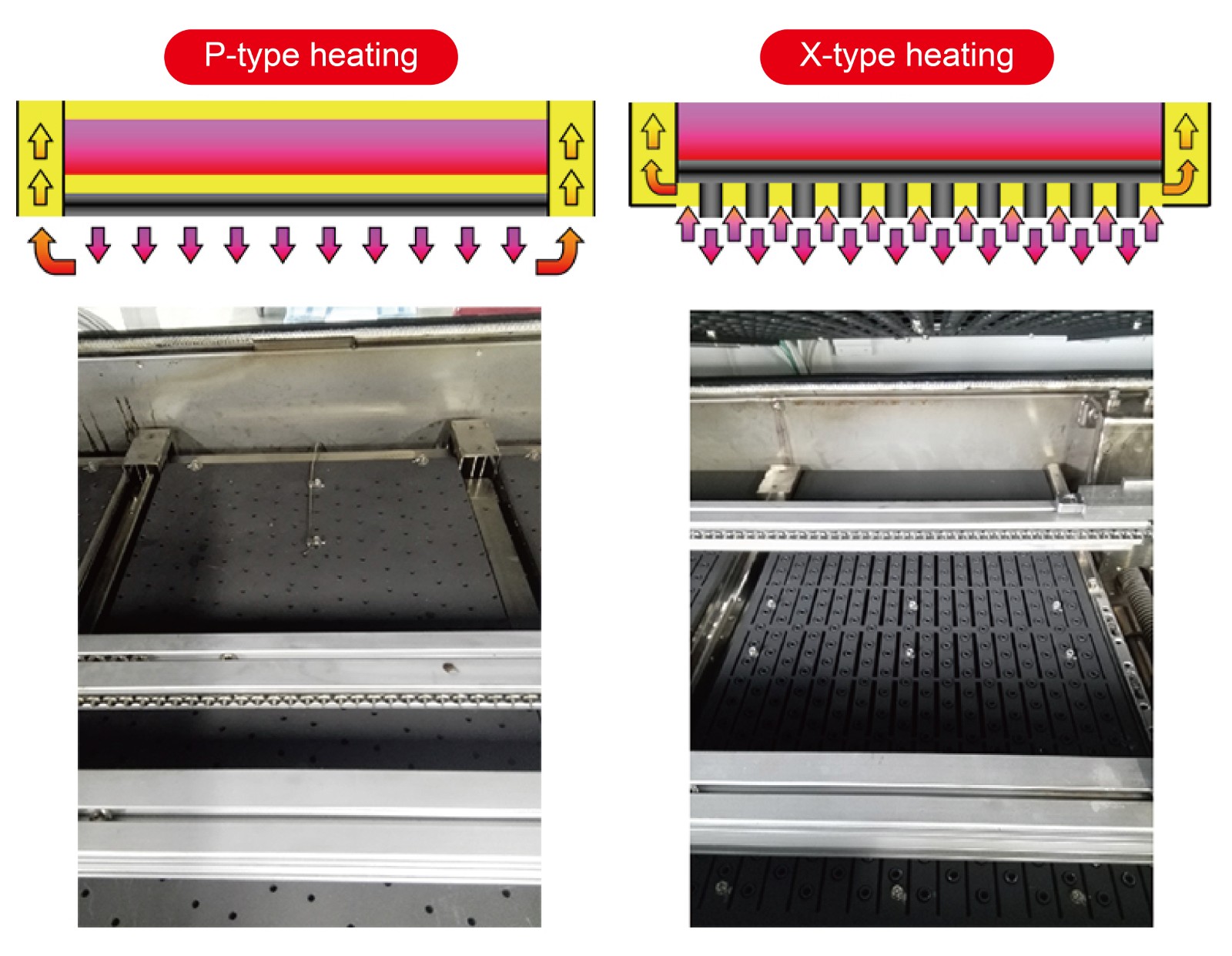

Heating method

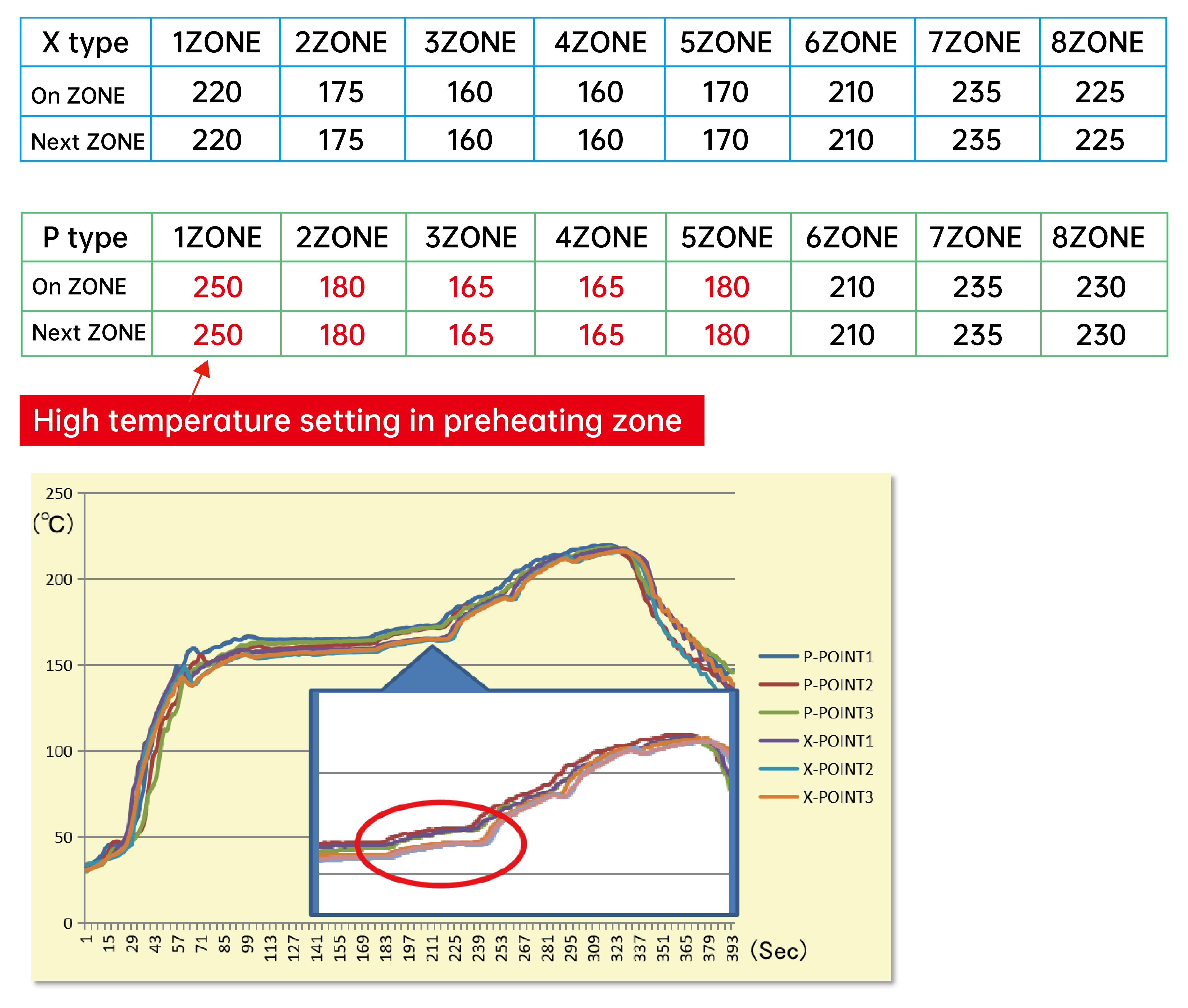

P-type heating • Blow out panel configuration • Hot air heating inside the small hole • Hot air recovery on both sides of the temperature zone | X type heating • Add a small circular nozzle to blow out the panel • Heating inside the small circular nozzle • Hot air recovery around each small circular nozzle |

Comparison of Heating Capacity between Ptype and Xtype

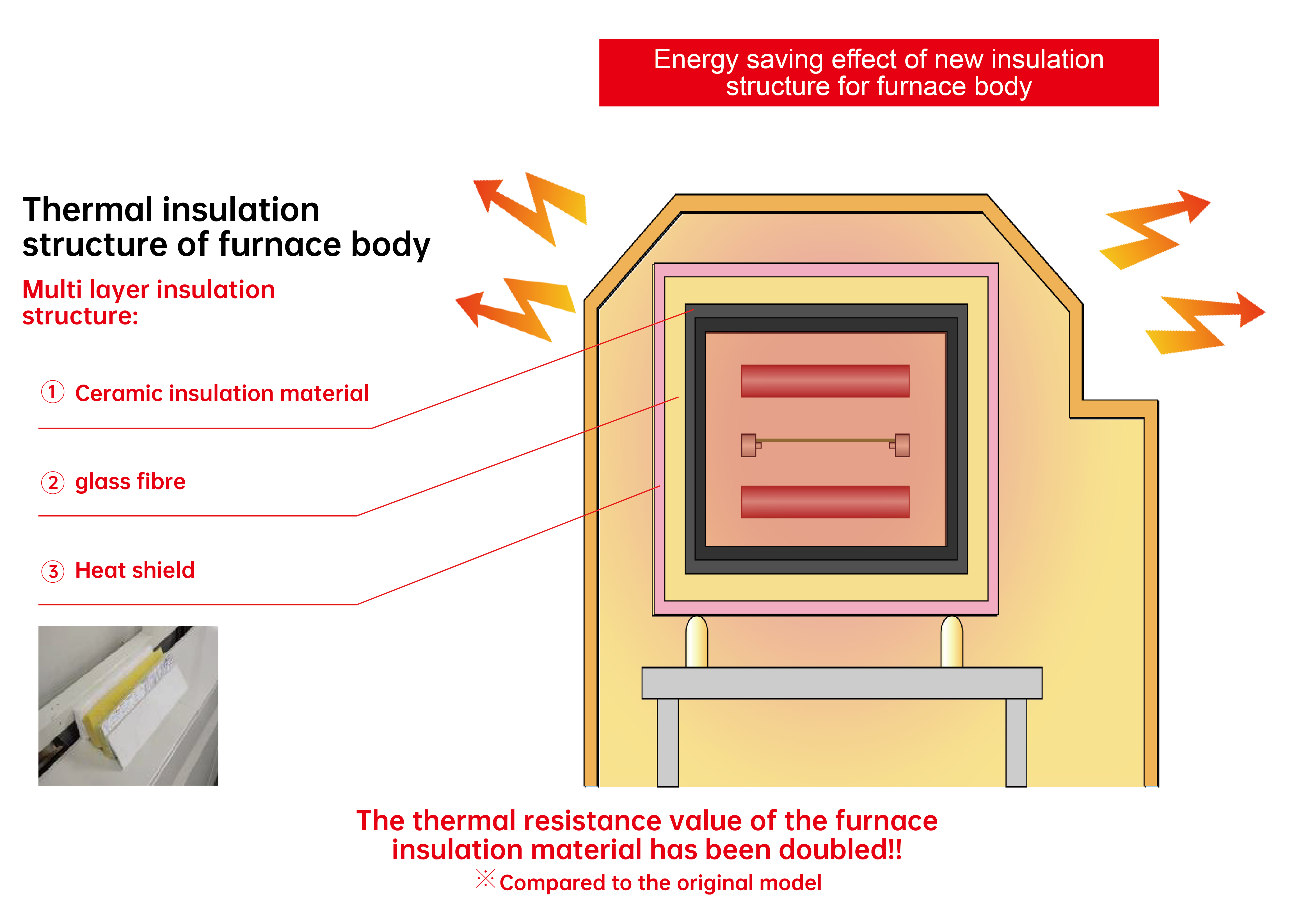

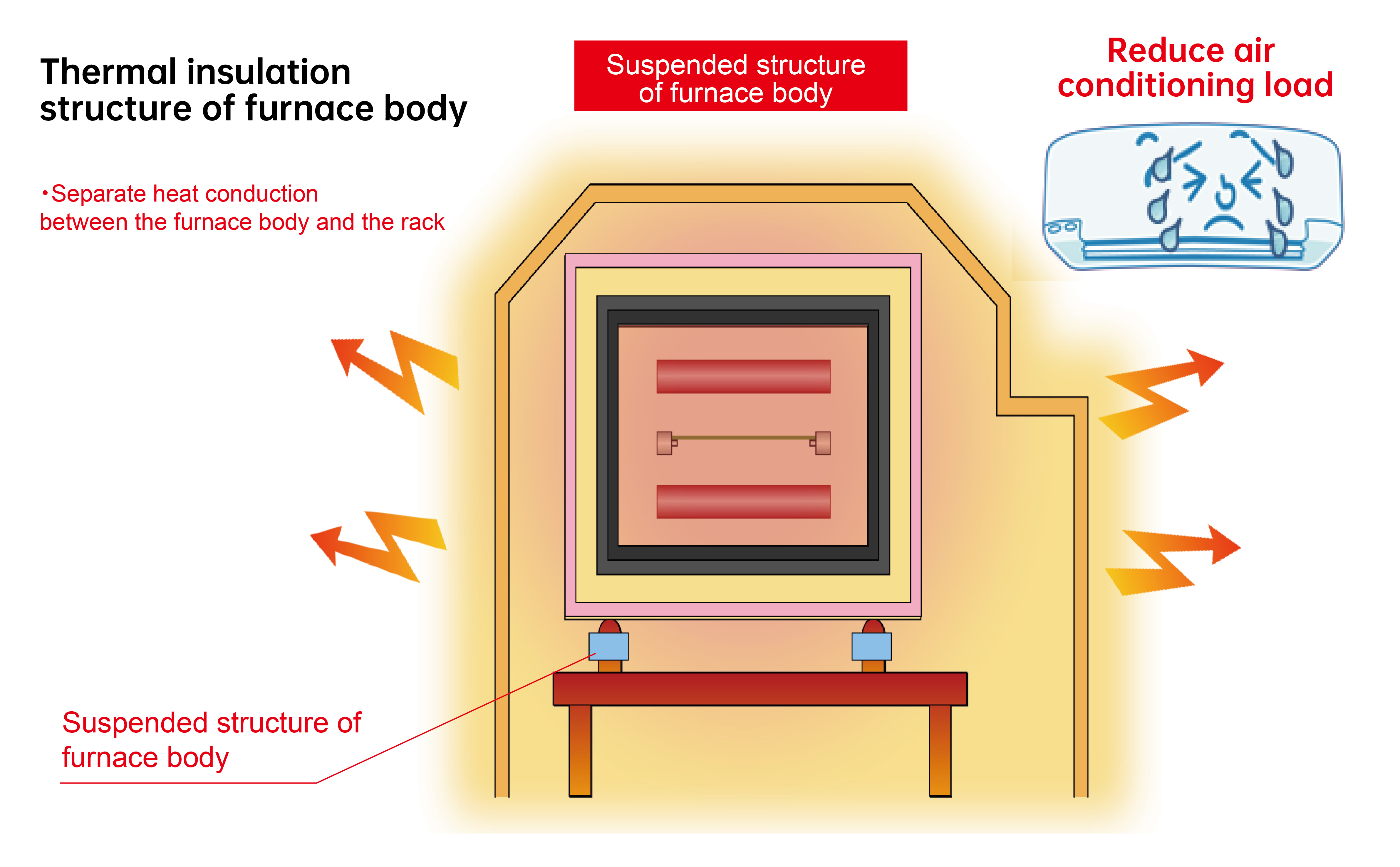

Thermal insulation structure 1/2

• Thermal insulation performance

• COST

• Construction for long-term use

Thermal insulation structure 2/2

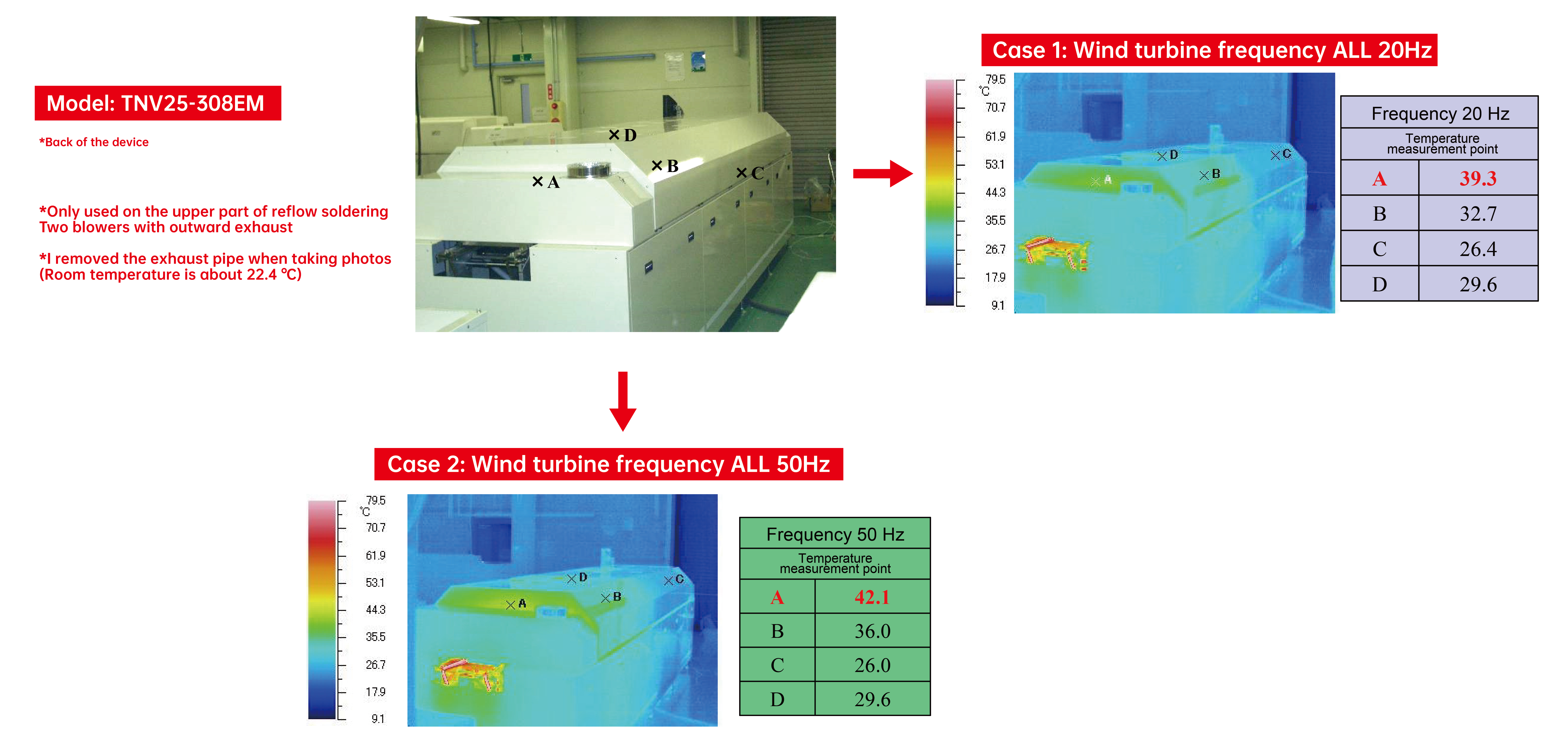

Surface temperature

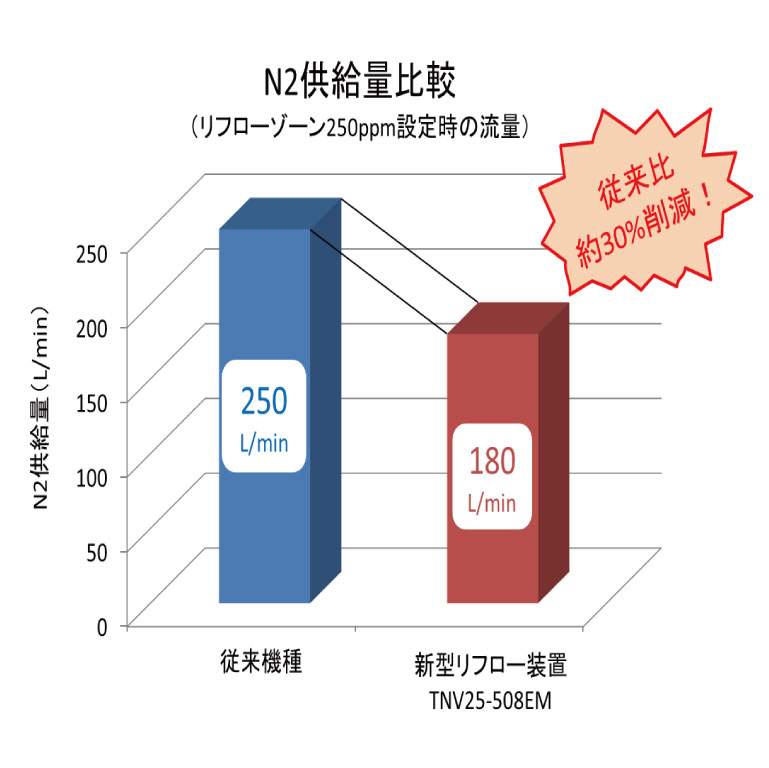

Nitrogen supply quantity

Significant reduction in nitrogen consumption: 180L/min (below 250ppm)

• Newly developed furnace structure to reduce nitrogen overflow

• Independent adjustable motor to achieve optimal circulation pressure/flow rate of hot air

• Stable oxygen concentration can also be achieved through continuous substrate input

• The oxygen concentration control system automatically controls the flow rate of N2

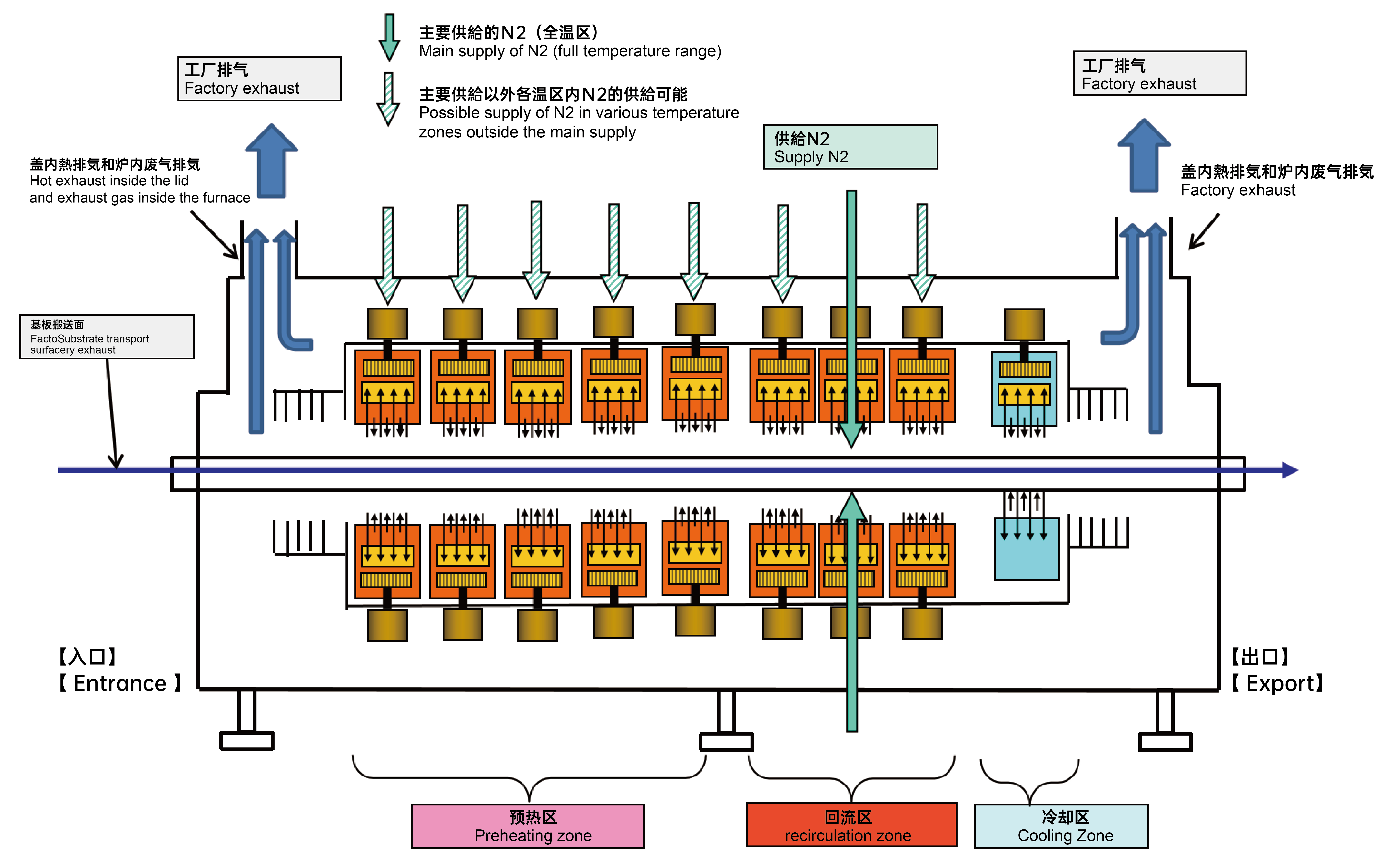

basic constitution

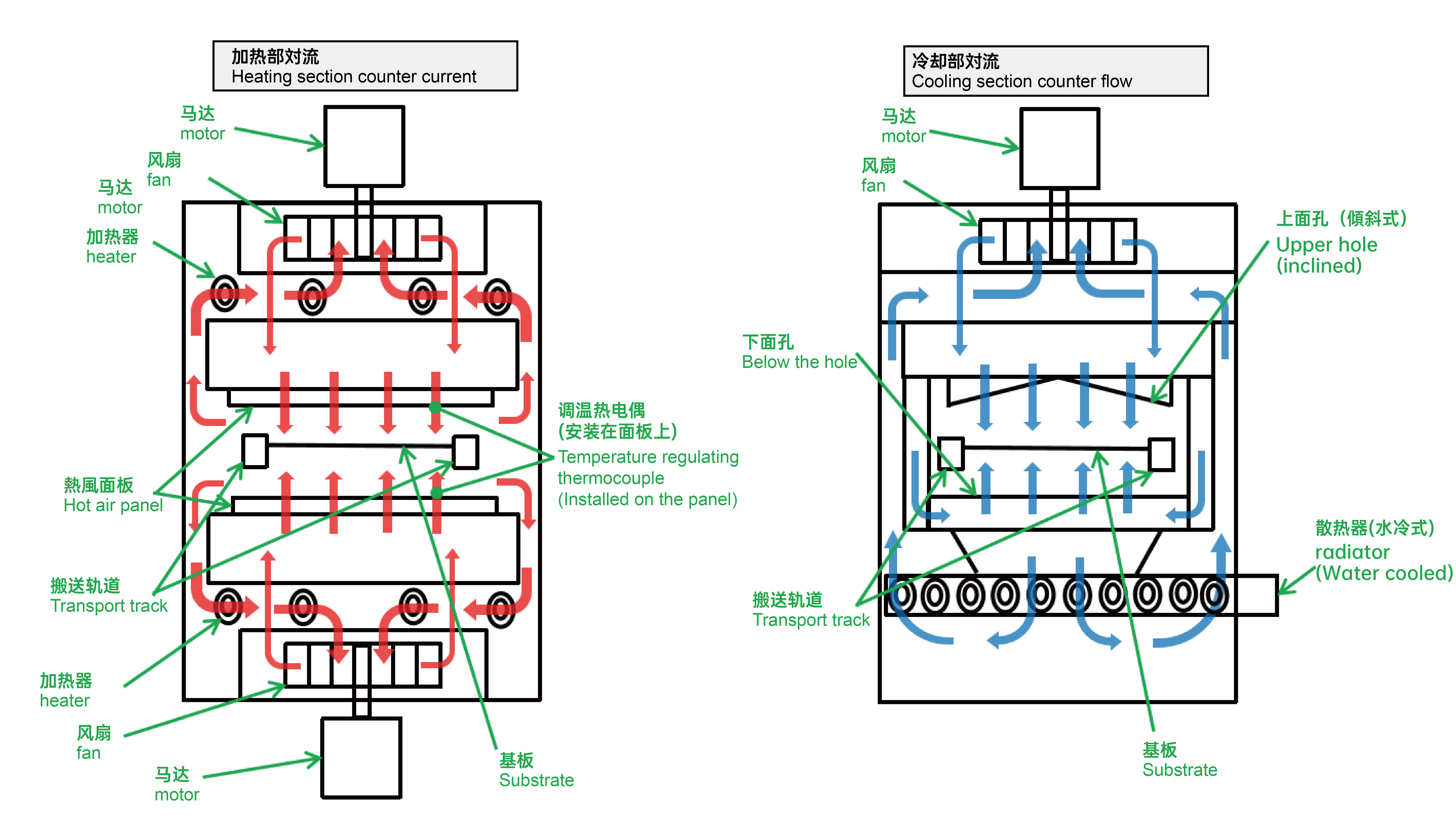

Sectional structure

• The same heating unit, temperature and air volume can be individually set and controlled, and temperature curves under various conditions can correspond.

• Thermoelectric coupling lines are installed on the panel to directly measure the temperature of hot air. (Set value=hot air temperature)

• The upper fan can circulate up and down.

• The lower water-cooled radiator ensures strong, effective, and stable cooling capacity.

Maintainability

• No tools required

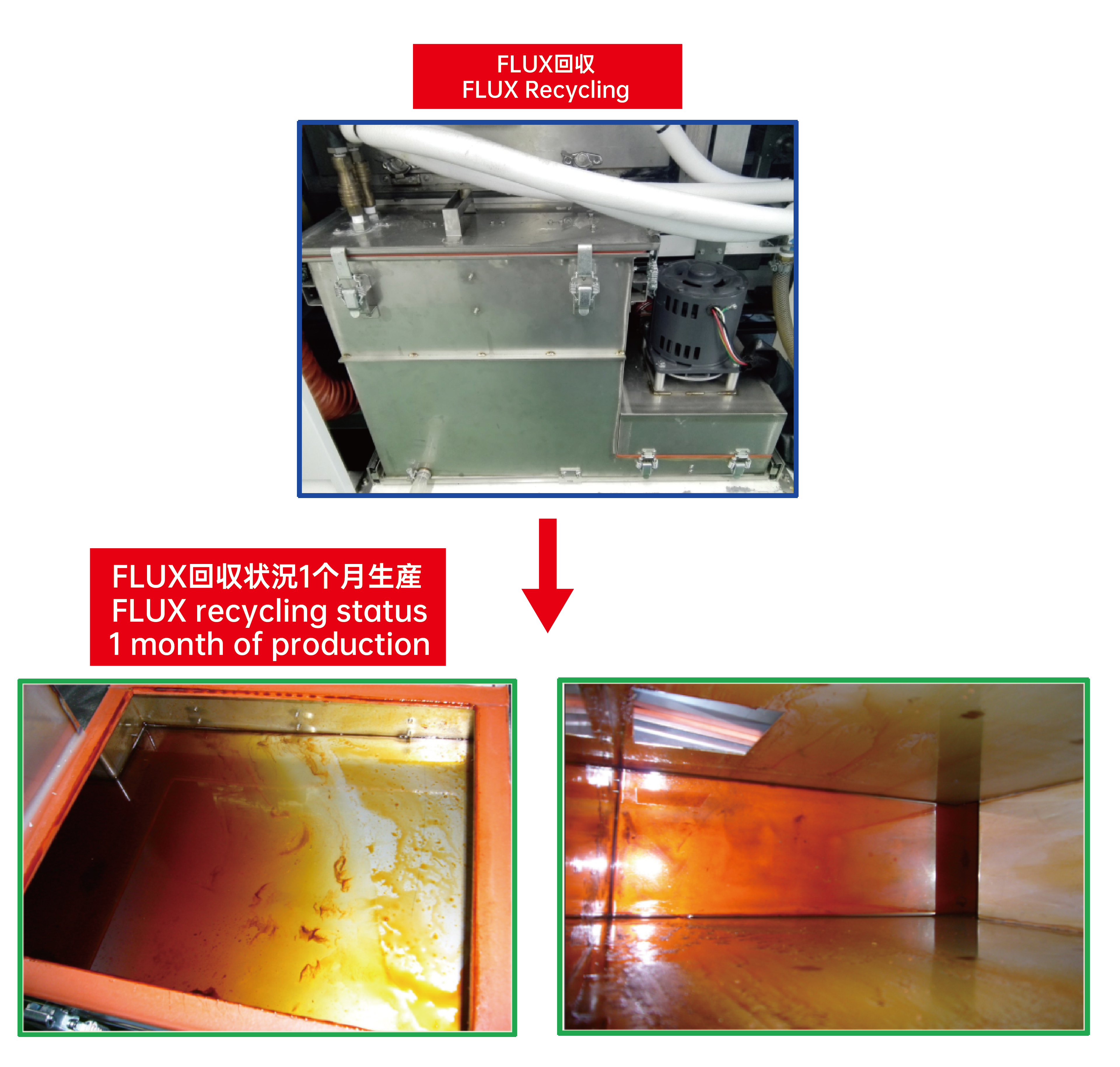

• FLUX centralized recycling

Operability 1/3

Operation screen 17 inch LCD screen

• The screen is clear at a glance

• Continuing the inherent system of operation and shortening the training time for introducing new machines

Can save photos and documents of various substrates (in JPG format)

• Confirmation of product and special notes when switching materials

QR Scan