Hot LIne:

0769-88087226

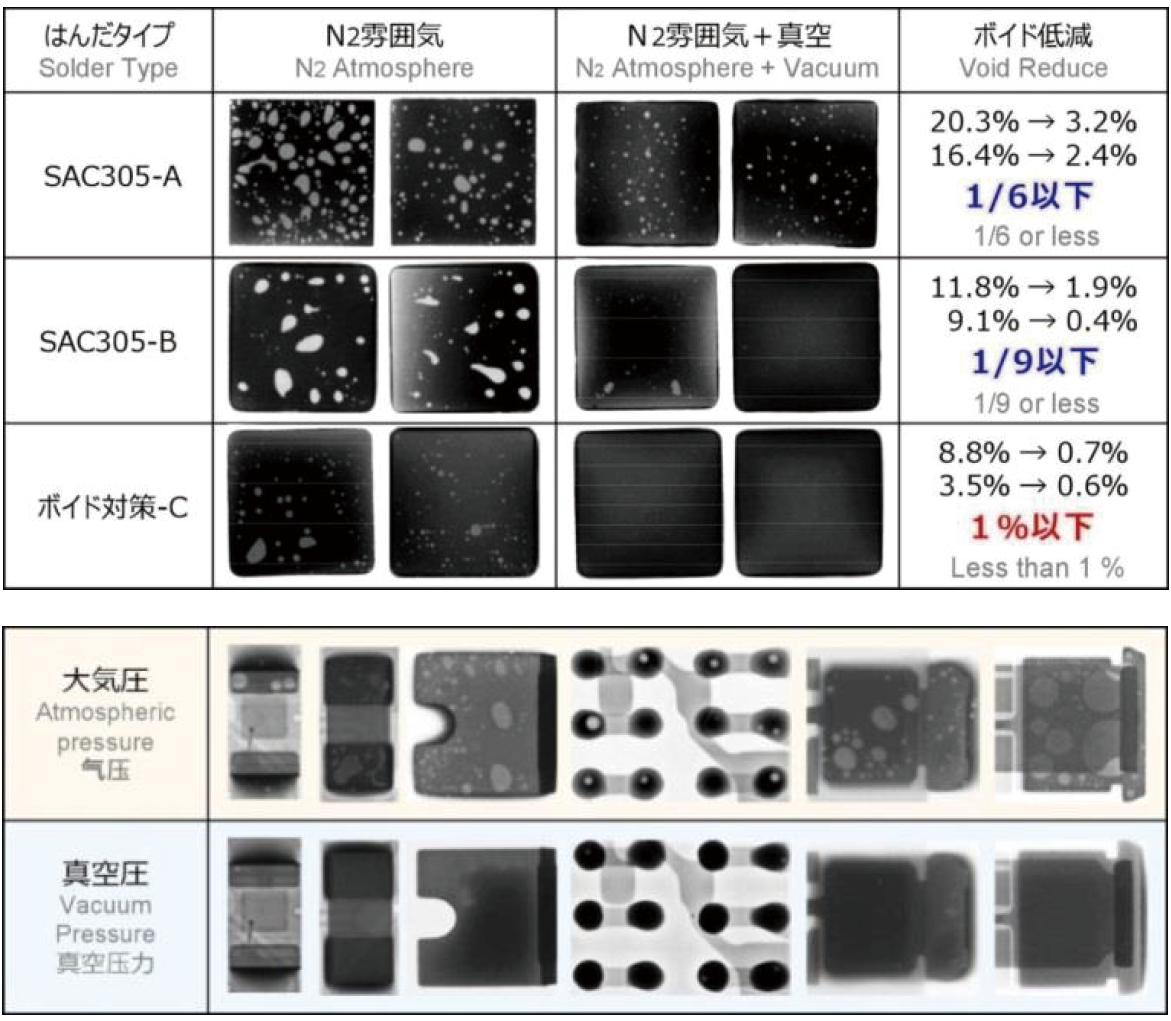

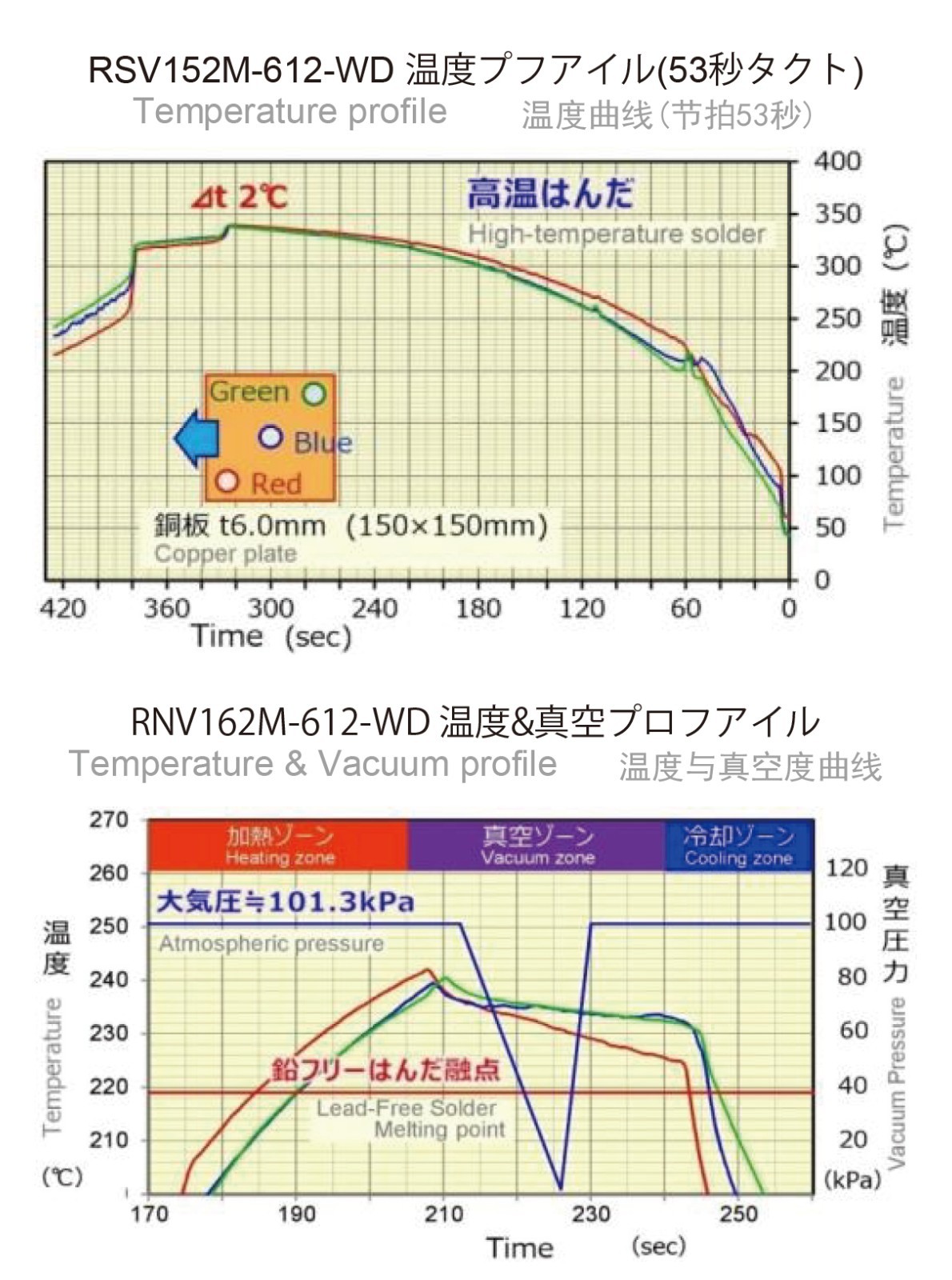

Vacuum Effect 1: Reduce Bubbles

The combination of hot air circulation heating and vacuum pressure, even for large-area component welding, can significantly reduce bubbles in a short period of time. Using solder paste corresponding to bubbles can achieve a bubble rate of less than 1%

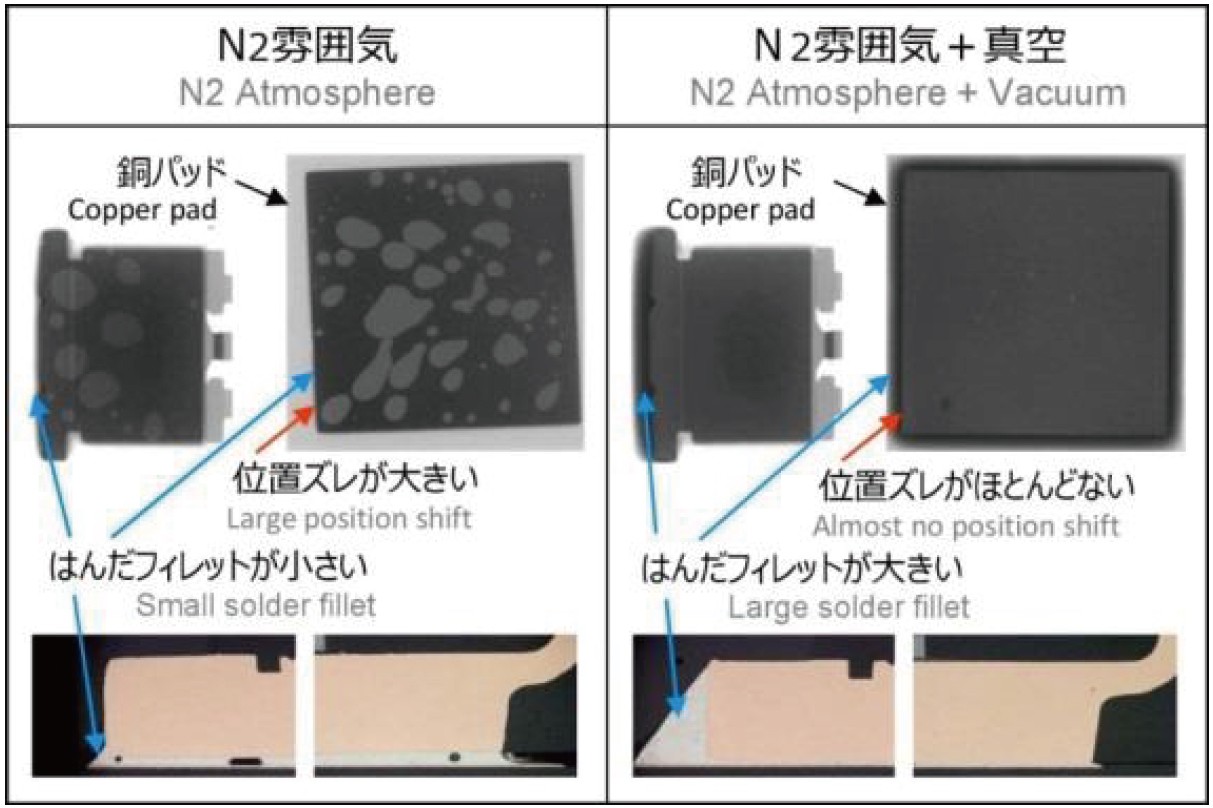

Vacuum Effect 2: Effects Other than Bubbles

• Welding automatic adjustment force increases, parts shift, and floating defects decrease

• Tin filling increases in size, facilitating visual inspection

Flux recycling system

The large capacity of the flux recycling device significantly reduces the cleaning frequency of the flux and improves the operating time of the equipment. The replacement and cleaning of heat exchangers are simple and easy to operate.

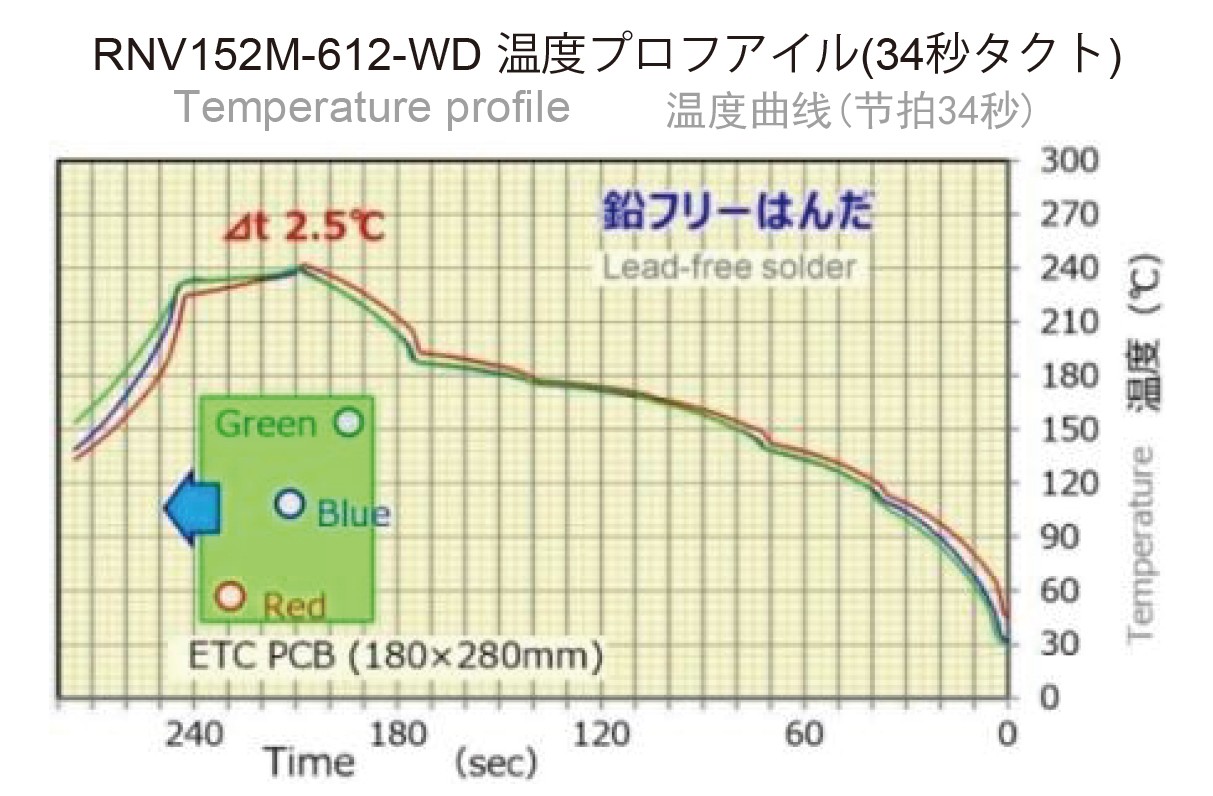

Up and down hot air circulation heating method

• Compared to the heating method of the heating plate, the temperature fluctuation is small, the thermal conductivity is high, and the reflux time is short

• It can also correspond to the welding of aluminum radiator circuit board components

• Vacuum reflow soldering of double-sided surface mounted circuit boards and a single vacuum reflow soldering can significantly reduce the bubbles on the double-sided board

heating performance

•The combination of upper and lower hot air circulation and vacuum pressure can achieve high-quality welding performance far beyond the traditional reflow soldering concept, even in a small temperature zone.

Ultra low power consumption with the lowest environmental impact

Lightweight and high insulation of the furnace body, achieving ultra-low energy consumption, saving energy, and reducing CO2 emissions. Energy saving, emission reduction, and cost saving. (Save 40% of energy)

Product parameters

QR Scan